Welcome to Pillow Plate India Laser Welded Pillow Plate Machine Manufacturer

Welcome to Pillow Plate India Laser Welded Pillow Plate Machine Manufacturer

WELD WHICH LOOKS GOOD PERFORMS GOOD

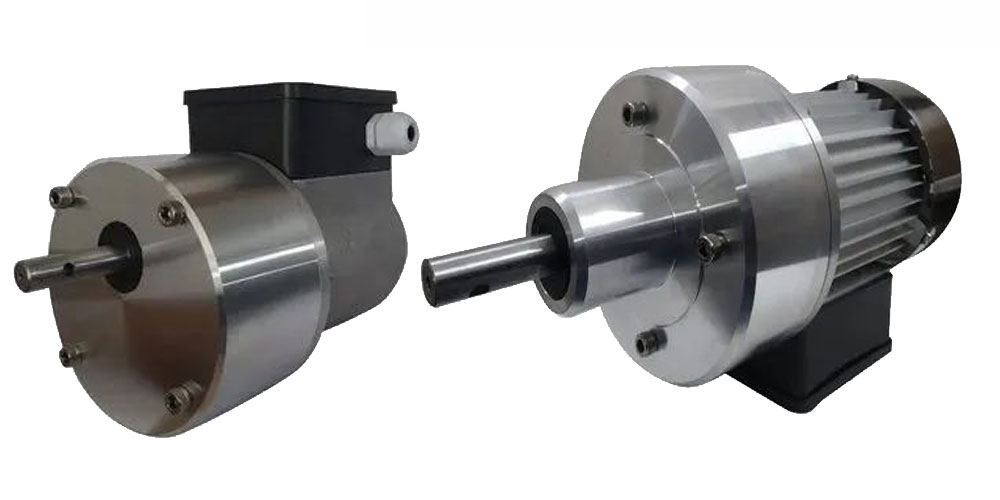

We manufacture agitator motors for milk cooling applications.The product is designed to bear the swinging load of the blade.

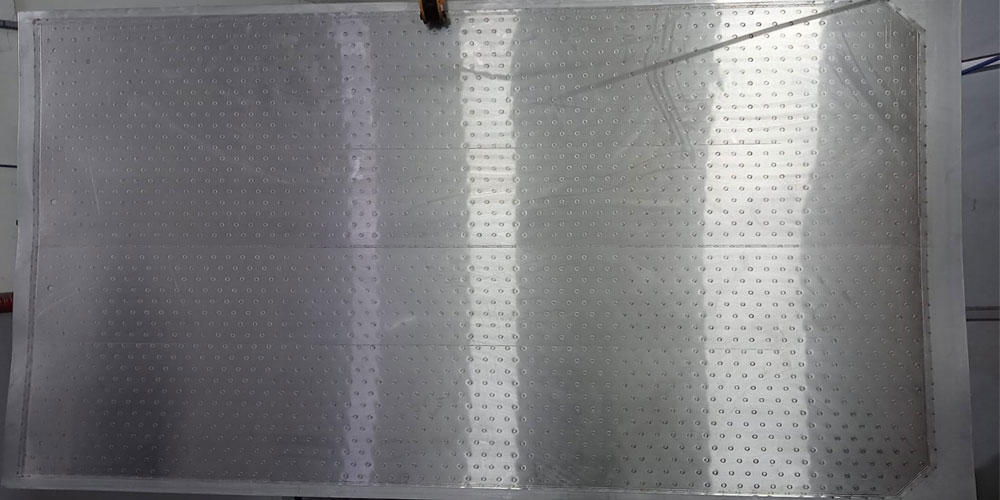

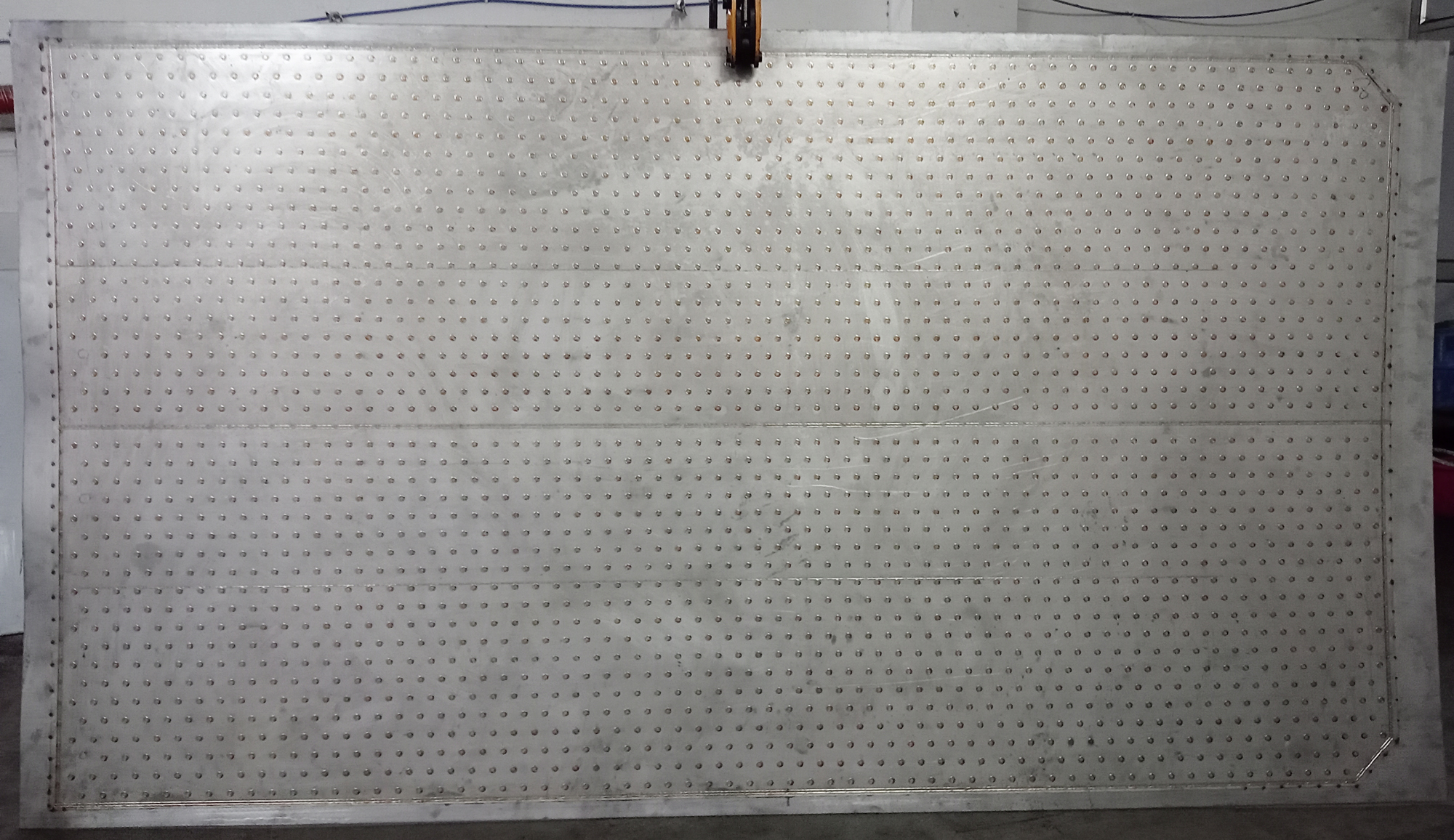

Pillow Plates are formed with two welded stainless steel sheets, continuously spot-welded together along the edge of the outer join.

Excellent weld quality is of the utmost importance in stainless steel overlap welding. Better accuracy and design of the machine results in High-quality welds with little or no distortion and consistent depth of weld from starting to end. Rigidity of the machine and software enables trouble free production Running and maintainence cost of the machine is really low as it has no consumable except some spare parts. The system integration has been done to produce best quality pillow plates.

1)Consistent depth for best quality weld-As we are using hydraulics bars to compress sheet and water coolled base. We can assure best quality weld and consistent depth.

2)Minimum gap-A gap of more than one-tenth of the upper sheet may result in poor quality weld.Our constant efforts to reduce the gap have resulted in a top quality weld.

3 Warpage control-As a large amount of welding has to be done warpage control is of the utmost importance.No gap and consistent welding depth has resulted in complete warpage control.

MF Engineers is a manufacturer of pillow plates & Milk Agitator/Geared motor.A pillow plate is a fully laser welded heat exchanger plate.They are designed to handle the desired pressure and are the most suitable for large cooling surface requirements.

After 2 years research and hard work, lack of sleep, and constant learning our company has devloped a pillow plate machine.

Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

We provide innovative product solutions for sustainable progress. Our professional team works to increase productivity and cost effectiveness on the market.